Good news! I have discovered a really quick and easy way to make the DRL fitment a whole lot easier.

Like most people, I started by modifying the replacement 'bulbs' to make them fit the light housing. This was a fairly tricky process and often results in damage to the bulbs while grinding off material around the boss area to make the diameter smaller. This can also compromise the O ring seal and allow water to get into the light, causing condensation. Closer examination of the light unit shows that the problem is not really the bulb dimensions, but the reflector aperture

behind the boss. It then occurred to me that simply reaming out the reflector housing might do the trick. Digging around in my drill box I found a 'stepped' drill (which happened to be imperial) and the largest diameter was 3/4" (about 19mm) Most of the LED replacements seem to be around 18mm diameter so that would allow plenty of clearance - no modification to the bulb is required. Only the reflector is modified, the light unit is undamaged and the job looks like OEM - you cannot see any signs of the mod from the outside.

Carefully inserting the stepped drill at the right angle, it passes through the mounting boss and only reams out the reflector

10 seconds later (after blowing out the swarf with an airline) I was finished - now I can fit just about any LED bulb I fancy. I went for a super-bright CREE which slotted straight in and works a treat.

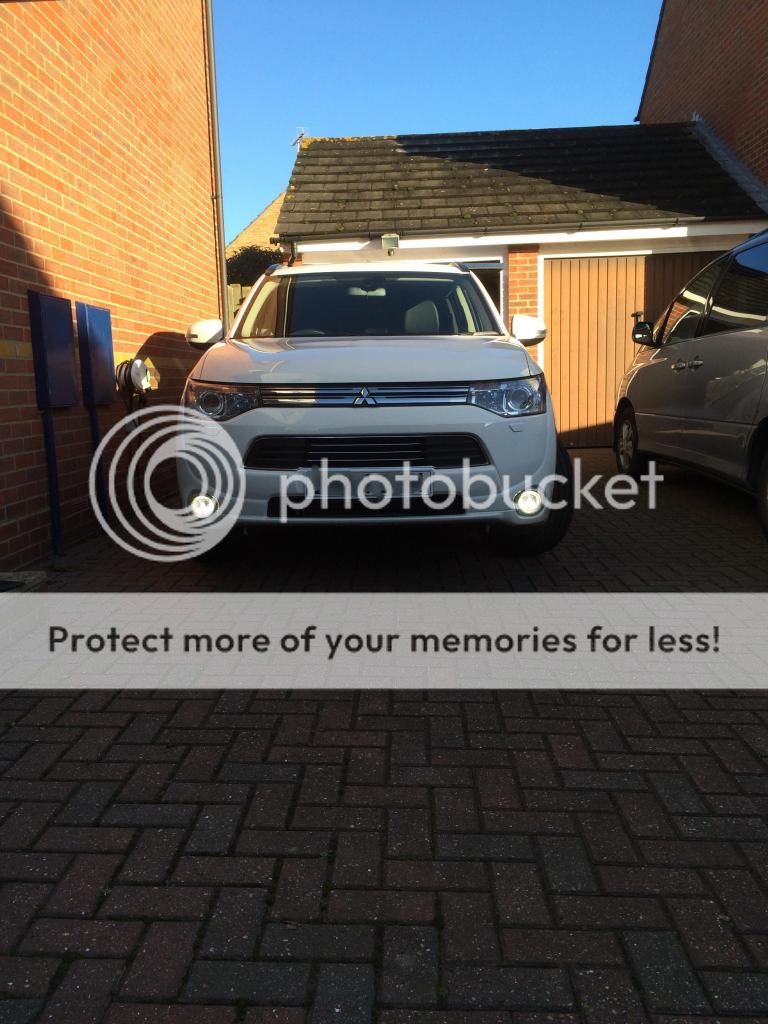

Brilliant! ...... literally! No more yellow halogens and less power consumption too.